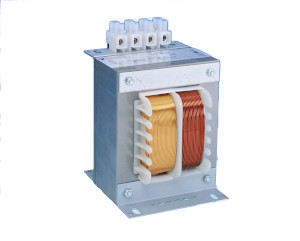

Transformers

About transformers

A transformer is an electrical device without moving parts. Its function is based on electromagnetic induction, thus it works only with alternating current. The main job for a transformer is to change voltage, lower or higher. A transformer can also be used to galvanically separate circuits which still must transfer energy. One reason for using alternating current in distributing electricity is that it is easy to change voltage levels efficiently.

About transformer characteristics

Power

The power of a transformer is reported in nominal power [S], the unit of which is VA. The nominal power is secondary voltage times secondary current. Sometimes it is advantageous to know the input power of the transformer to help determine the size of the input cable and/or fuse. This is why the data sheet also gives ΔS. Since all transformers have bigger or smaller copper, iron, and magnetization losses, ΔS is always greater than 1. When a transformer is connected to an electrical circuit there is always a surge current, thus a slow blow fuse should be connected in front of the primary winding.

No load voltage

A transformer always has load losses (copper losses), so that secondary voltage changes according to loading. The defined secondary voltage is always reported with a defined load. So that we can calculate changes in secondary voltage, the data sheet reports Δ U. The no load voltage can be calculated by multiplying the defined voltage by ΔU. (Example: secondary voltage given as 110 V and ΔU=1.05. The no load voltage is thus: 1.05 X 110 V = 115.5 V. Secondary voltage thus varies from 110 V at normal load to 115.5 V with no load).

Efficiency

Deviations from type power

Auto-transformers

3-phase vector groups

3-PHASE VECTOR GROUPS

Encapsulation classes

|

1st number |

Description | Definition |

|

IP 0X |

Non-protected | – |

|

IP 1X |

Protected against solid foreign objects with a diameter of 50mm and greater | The object probe, a sphere 50mm diameter, shall not fully penetrate. |

|

IP 2X |

Protected against solid foreign objects with a diameter of 12.5mm and greater | Protected against solid foreign objects with a diameter of 12.5mm and greater |

|

IP 3X |

Protected against solid foreign objects with a diameter of 2.5mm and greater | The object probe, a sphere 2.5mm diameter, shall not penetrate at all. |

|

IP 4X |

Protected against solid foreign objects with a diameter of 1mm and greater | Protected against solid foreign objects with a diameter of 1mm and greater |

|

IP 5X |

Dust-protected | Ingress of dust is not totally prevented, but dust shall not penetrate in a quantity to interfere with satisfactory operation of the apparatus or to impair safety. |

|

IP 6X |

Dust-tight | No ingress of dust (at a partial vacuum of 20mbar inside the enclosure). |

|

2nd number |

Description | Definition |

|

IP X0 |

Non-protected | – |

|

IP X1 |

Protected vertically falling water drops | Vertically falling drops shall have no harmful effects. |

|

IP X2 |

Protected vertically falling water drops when the enclosure is tilted up to 15º | Vertically falling drops shall have no harmful effects when the enclosure is tilted at any angle up to 15º on either side of the vertical. |

|

IP X3 |

Protected against spraying water | Water sprayed at an angle of up to 60º on either side of the vertical shall have no harmful effects. |

|

IP X4 |

Protected against splashing water | Water splashed against the enclosure will enclosure from any direction shall have no harmful effects. |

|

IP X5 |

Protected against water jets | Water projected in jets against the enclosure will enclosure from any direction shall have no harmful effects. |

|

IP X6 |

Protected against powerful water jets | Water projected in powerful jets against the enclosure will enclosure from any direction shall have no harmful effects. |

|

IP X7 |

Protected against the effects of temporary immersion in water | Ingress of water in quantities causing harmful effects shall not be possible when the enclosure is temporarily immersed in water under standardized conditions of pressure and time. |

|

IP X8 |

Protected against the effects of continuous immersion in water | Ingress of water in quantities causing harmful effects shall not be possible when the enclosure is continuously immersed in water under conditions which shall be agreed between the manufacturer and the user but which is more severe than for numeral 7. |

Standard type structures

The E-series transformers are normally wound to double section and chokes single section bobbin. In applications, where better coupling between primary and secondary is needed, transformers could also be wound to single section bobbin.

Items to be mentioned in ordering

- type

- power

- primary and secondary voltage; also secondary current as well, if there are to be taps or a separate winding connection

- connection group, 3 phase transformers

- possible fuse or over current protection

- other information such as frequency, cyclic use, auto-transformer, etc.